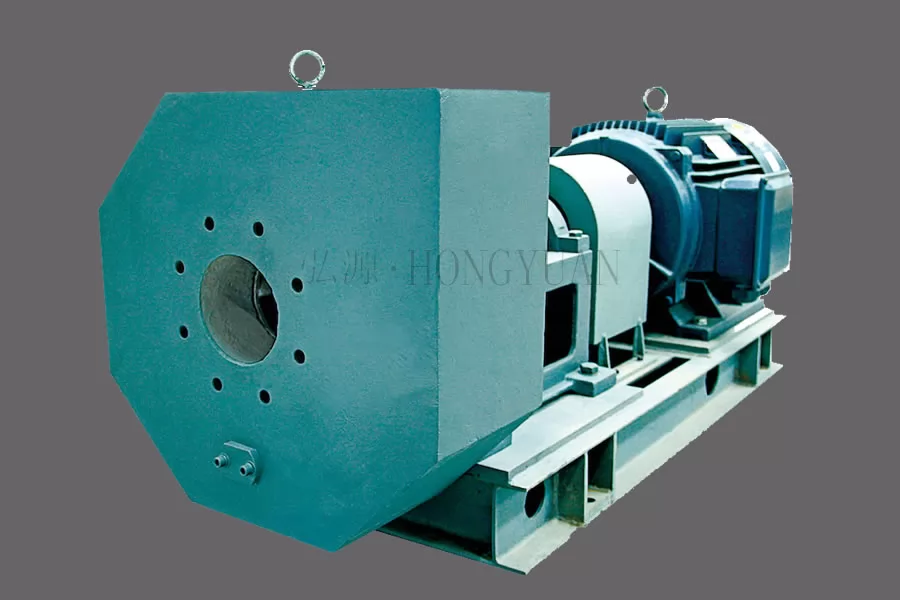

Slurry Pump Solutions Made in China

China has become one of the most important manufacturing bases for slurry pumps, supported by a large industrial ecosystem and decades of engineering experience. The slurry pump industry includes a wide range of manufacturers specializing in mining pumps, gravel pumps, horizontal and vertical slurry pump systems, as well as wear-resistant materials and spare parts. Many production hubs—such as those in Hebei, Shandong, and Zhejiang—have developed strong capabilities in casting, machining, hydraulic design, and OEM component production. This environment enables Chinese suppliers to provide a broad selection of slurry pumps suitable for mining, mineral processing, coal preparation, sand washing, dredging, and other heavy-duty applications.

China’s Slurry Pump Industry

The slurry pump sector in China has grown through continuous investment in casting technologies, high-chromium wear-resistant alloys, and rubber molding processes. Manufacturers generally offer pumps that follow international design standards, including common configurations compatible with established global models. Because of extensive supply chain for impellers, casings, bearing assemblies, seals, and frames, complete pumps and replacement parts can be produced with consistent quality and stable lead times. The industry places emphasis on heavy-duty centrifugal slurry pumps, which are widely used for transporting abrasive and high-density slurries in mining and industrial environments.

Why Many Buyers Choose Slurry Pumps from China

A key reason buyers select Chinese slurry pumps is the balance between durability and cost. The combination of large-scale production and established material technologies allows manufacturers to offer competitive pricing without sacrificing essential performance. Many suppliers are experienced in providing engineering support, customization options, and technical drawings based on customer requirements. For users who need pumps for mining, sand processing, tailings transportation, or similar operations, Chinese suppliers can deliver pumps in a wide range of sizes, materials, and configurations, often with shorter delivery times compared to overseas alternatives.

China’s Role in the Global Slurry Pump Market

China plays a significant role in supplying slurry pumps to international markets, including Asia, Africa, South America, and the Middle East. Chinese manufacturers produce both full pump systems and spare parts used in large-scale mining and industrial projects. Because many facilities are capable of producing components compatible with widely used international slurry pump designs, global buyers can source reliable equipment and replacement parts through suppliers. The combination of manufacturing capacity, technical familiarity with heavy-duty slurry pump applications, and strong export experience has made China an essential participant in the worldwide slurry pump supply chain.

Slurry Pump Manufacturing Advantages in China

Cost Efficiency in Slurry Pump Production

China’s slurry pump industry benefits from large-scale manufacturing, which helps reduce overall production costs while maintaining the performance required for mining, mineral processing, sand washing, and other abrasive slurry handling. Access to domestic raw materials and established regional factories contributes to stable and competitive pricing for a wide range of pump models and wear parts.

Advanced Materials and Casting Technologies

Chinese manufacturers have long focused on improving materials and casting processes for slurry pumps. High-chromium wear-resistant alloys, rubber lining techniques, precision machining, and controlled heat-treatment methods are widely used. These capabilities support the production of durable impellers, volutes, casings, and other components essential for heavy-duty centrifugal slurry pumps operating in harsh conditions.

Integrated Industrial and Supply Chain Network

One of China’s strengths is the completeness of its slurry pump supply chain. Industrial clusters include foundries, machining centers, bearing and seal suppliers, motor manufacturers, and assembly facilities. This integration enables efficient production flow, shorter lead times, and more stable quality, making it easier to meet diverse application requirements across different industries.

OEM and ODM Capabilities for Global Compatibility

Many Chinese slurry pump manufacturers provide OEM and ODM services and produce pumps compatible with widely used international designs. This includes models used in global mining, dredging, and industrial operations. The ability to supply interchangeable parts and tailored configurations supports customers who need flexibility in maintaining or upgrading existing slurry pump systems.

Key Manufacturing Regions in China

Major slurry pump production areas—such as Hebei, Shandong, and Zhejiang—are home to extensive casting, machining, and assembly facilities. These regions form specialized industrial clusters with strong technical experience and export capacity. Their combined resources play a significant role in position as a reliable global supplier of slurry pumps for abrasive and high-density slurry transport.

China Slurry Pump Product Portfolio

Slurry Pump Technology and Design in China

Hydraulic Design of Slurry Pumps

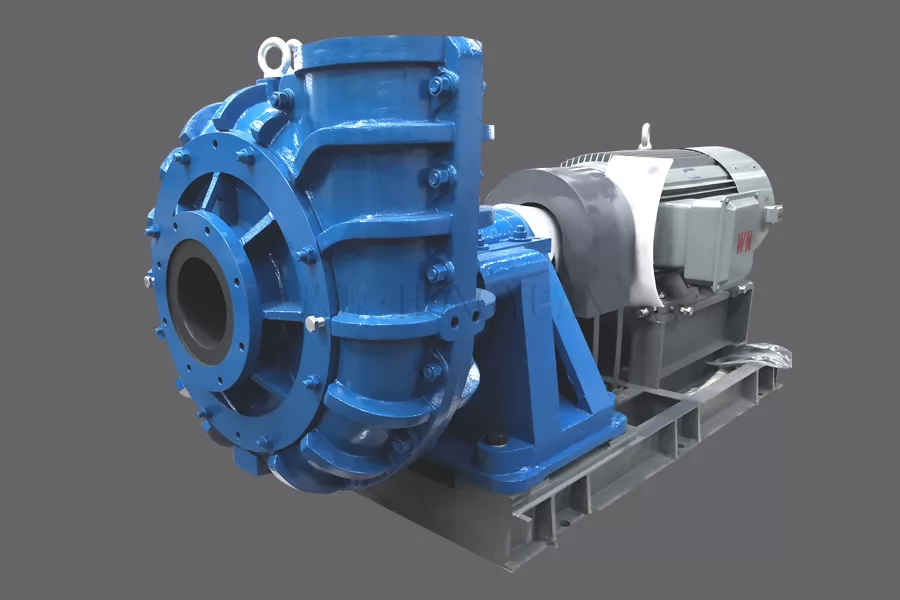

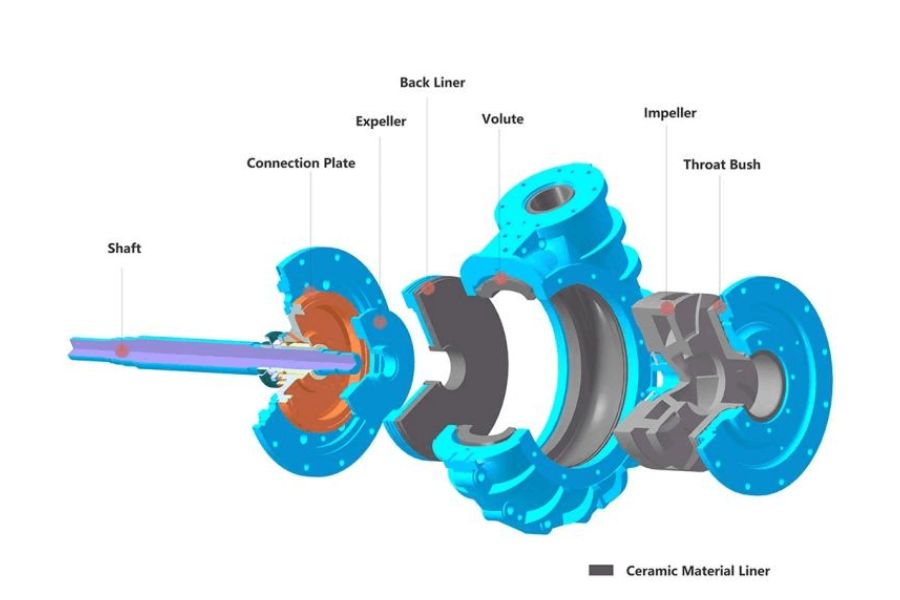

Chinese slurry pump manufacturers place great emphasis on hydraulic design to improve efficiency and reduce wear during the transport of abrasive slurries. The geometry of impellers, volute chambers, and flow passages is optimized to handle high-density materials while maintaining stable pressure and smooth flow. Many factories apply computational analysis and long-term field testing to refine hydraulic performance for mining, mineral processing, and dredging applications.

Wear-Resistant Materials for Slurry Pumps

Durable materials are essential in slurry pump construction. Commonly used wear-resistant options include high-chrome alloys such as A05 and A49, rubber linings for corrosive or fine-particle slurries, and customized metallurgy for severe abrasion environments. These material selections help extend the service life of wet-end parts such as impellers, liners, and casing components, ensuring consistent performance in demanding operations.

Slurry Pump Shaft Seal Options

The shaft seal structure is a critical aspect of slurry pump design. Chinese manufacturers typically provide several sealing options, including mechanical seals for enhanced leak control, packing seals for easy maintenance, and expeller (centrifugal) seals for environments where clean water sealing is limited. The availability of multiple sealing types allows users to match the pump to specific operating conditions and slurry characteristics.

Bearing and Drive Systems for Slurry Pumps

Reliable bearing assemblies and drive systems contribute significantly to slurry pump longevity. Factories in China usually incorporate heavy-duty bearings, robust housings, and precise alignment structures to handle high loads and prolonged operation. Drive configurations may include direct drive, belt drive, or variable-speed systems, enabling operators to fine-tune pump performance based on site requirements.

Performance Curves and Efficiency Optimization

Performance curve analysis is widely used to ensure the correct slurry pump selection and optimal efficiency in the field. Chinese manufacturers provide detailed head, flow, and power curves to guide users in matching pump models with operating conditions. Ongoing improvements in hydraulic design, material selection, and motor control systems contribute to better energy efficiency and more consistent output across a range of industrial applications.

Comparison Between Chinese Slurry Pumps and Global Brands

Performance Comparison of Slurry Pumps

In recent years, Chinese slurry pump manufacturers have significantly improved hydraulic design, casting quality, and assembly precision, resulting in performance levels that align closely with many established global brands. While premium international brands such as Warman, Metso, and GIW remain industry benchmarks, Chinese pumps generally offer stable flow capacity, reliable head performance, and competitive efficiency for most mining, mineral processing, and dredging operations. Performance consistency varies by manufacturer, but many leading factories have demonstrated strong capability in producing heavy-duty pumps for abrasive slurry transport.

Cost Comparison of Slurry Pumps

One of the most recognized advantages of slurry pumps is their cost competitiveness. Local production resources, mature supply chains, and high-volume manufacturing allow factories to offer pumps and wear parts at substantially lower prices compared to global brands. This cost advantage applies not only to complete pumps but also to essential components such as impellers, liners, and shaft sleeves, making China a preferred sourcing hub for budget-conscious or large-scale operations.

Service Life Evaluation for Slurry Pumps

Service life varies depending on material selection, slurry characteristics, and operating conditions. While top-tier global brands may still deliver longer wear life in extremely harsh environments, many Chinese manufacturers utilize high-chrome alloys, rubber linings, and refined casting processes that provide solid durability for general heavy-duty applications. With proper maintenance and appropriate material matching, slurry pumps can achieve operational lifespans suitable for mining and industrial workflows, offering a practical balance between longevity and cost.

Compatibility with Warman Metso GIW Models

A notable strength of China’s slurry pump industry is the widespread availability of models and parts compatible with major international brands such as Warman, Metso, and GIW. Many factories produce pumps following similar structural standards, allowing users to find replacement components—including wet-end parts, bearing assemblies, and seals—without redesigning their existing systems. This compatibility simplifies maintenance, reduces downtime, and offers a cost-effective alternative for operations seeking reliable aftermarket solutions.

Slurry Pump Applications Across Key Industries

Mining and Mineral Processing

Slurry pumps made in China play a major role in mining and mineral processing, where they are used to transport ore slurries, tailings, and concentrate. Their wear-resistant materials and stable hydraulic performance make them suitable for continuous operation in gold, copper, iron, and non-ferrous mineral sectors. Chinese manufacturers supply a wide range of pump sizes and configurations that fit common beneficiation processes such as grinding circuits, cyclone feed, flotation, and tailings disposal.

Sand Washing and Dredging

In sand washing plants, river dredging, and coastal engineering projects, Chinese slurry pumps are widely adopted due to their strong handling capability for sand, gravel, and high-solids mixtures. Many domestic manufacturers produce heavy-duty pumps designed for long-distance delivery and harsh abrasive conditions, supporting operations such as river desilting, sea reclamation, and large-scale sand extraction.

Metallurgical Industry

Slurry pumps are essential in metallurgical processes where high-temperature, corrosive, or abrasive slurries must be transported. Chinese pumps are used in steel plants, smelting operations, and metal refining systems for conveying slag slurry, mill scale, wastewater sludge, and other by-products. Consistent durability and material options help ensure reliable operation in these demanding industrial environments.

Flue Gas Desulfurization (FGD) in Power Plants

FGD systems rely heavily on slurry pumps to circulate limestone slurry and manage gypsum by-products. Chinese manufacturers provide corrosion-resistant and abrasion-resistant pump models designed specifically for wet flue gas desulfurization processes. Rubber-lined and duplex stainless-steel options are commonly used to ensure longer service life under acidic conditions found in power plant desulfurization units.

Chemical and Petroleum Industries

In the chemical and petroleum sectors, slurry pumps are used to handle mixtures containing solids, corrosive media, or industrial by-products. Many Chinese manufacturers supply pumps with specialized materials and sealing systems to meet chemical-process requirements. These pumps support operations such as catalyst handling, wastewater processing, and refinery sludge transport.

Construction, Coal, and Tunnel Engineering

Slurry pumps produced in China are widely used in construction and infrastructure projects, including tunneling, coal preparation, and building material production. Their ability to manage thick, abrasive, or sediment-heavy slurries makes them suitable for slurry shields, underground dewatering, coal washing, and cement-related processes. The versatility and cost-efficiency of slurry pumps support a broad range of engineering applications with demanding material-handling needs.

Quality Assurance in Chinese Slurry Pump Manufacturing

Raw Material Inspection

Quality assurance in China’s slurry pump industry begins with strict raw material inspection. Manufacturers typically analyze chemical composition, hardness, and metallurgical structure to ensure alloys such as high-chrome iron meet the standards required for abrasion-resistant pump components. Proper material selection is essential for producing durable impellers, liners, and casings capable of withstanding harsh slurry conditions in mining and industrial environments.

Casting and Heat Treatment

Chinese factories operate advanced casting workshops equipped with molding lines, precision melting systems, and controlled heat-treatment facilities. These processes help ensure stable wear resistance, improved toughness, and reduced internal defects in high-chrome and other alloy components. Heat treatment is carefully regulated to achieve the required hardness balance, which directly influences the service life of slurry pump wet-end parts.

Machining and Dynamic Balancing

After casting, slurry pump components undergo CNC machining, drilling, and finishing to achieve accurate assembly tolerances. Impellers, in particular, are subject to dynamic balancing to reduce vibration and improve overall pump stability. This level of precision contributes to longer bearing life, smoother operation, and consistent hydraulic performance across varying slurry conditions.

Performance Testing Procedures

Performance testing is an essential part of the quality control workflow. Many Chinese manufacturers operate test benches capable of measuring flow rate, head, power consumption, and efficiency. These tests verify that each pump model meets required performance curves and operates safely under expected loads. Testing also helps identify assembly issues before the pump is packed and delivered to customers worldwide.

Quality Certifications

To meet global market requirements, numerous slurry pump manufacturers comply with international quality standards such as ISO 9001 for quality management and CE certification for export to specific regions. These certifications reflect a commitment to consistent production processes, safety compliance, and traceable quality control. For industries requiring additional documentation, some suppliers also provide factory audits and third-party inspection reports.

Customization and Service for Chinese Slurry Pumps

OEM and ODM Customization Capabilities

Many slurry pump manufacturers in China provide strong OEM and ODM customization services, supporting tailored designs for specific industries or operating environments. This can include adjustments to pump dimensions, hydraulic configurations, material selections, motor options, and installation layouts. The ability to customize slurry pumps allows customers to optimize performance for mining, sand processing, dredging, chemical handling, and other abrasive slurry applications.

Engineering Selection Services

Accurate pump selection is essential for achieving stable and efficient slurry transport. Chinese manufacturers often provide technical support, including slurry data analysis, model recommendations, performance curve verification, and system design consultation. These engineering services help customers select the most appropriate pump type and configuration for their specific flow rates, slurry densities, and working conditions.

Installation and Maintenance Guidance

Proper installation and routine maintenance significantly influence the lifespan and reliability of slurry pumps. Many suppliers in China offer detailed installation guides, start-up instructions, and maintenance training. Guidance may cover alignment checks, seal adjustments, lubrication schedules, and wear inspection. This support helps users reduce downtime and maintain stable pump performance during continuous operation.

Global Spare Parts Supply

To meet the needs of international customers, Chinese slurry pump manufacturers maintain extensive spare parts inventories and export networks. Wear parts such as impellers, liners, casings, bearings, and seals can be supplied quickly to minimize equipment downtime. For operations using pumps compatible with global brands, many Chinese factories also offer interchangeable components to simplify maintenance and reduce procurement costs.

After-Sales Service and Customer Support

Reliable customer support is an important component of slurry pump industry. Manufacturers typically provide assistance through online consultation, remote troubleshooting, technical documentation, and warranty services. Some suppliers also collaborate with overseas partners to offer localized service when required. This combination of technical support and responsive after-sales service helps ensure long-term, dependable pump operation across various industrial applications.

Logistics and Delivery for Chinese Slurry Pumps

Standard Delivery Lead Time

Chinese slurry pump manufacturers generally offer stable and predictable delivery schedules due to their mature supply chains and large-scale production capacity. Standard lead times typically range from two to six weeks depending on pump size, material requirements, and customization needs. Common models and wear parts are often available in stock, allowing for faster dispatch to meet urgent project timelines.

Export Packaging

To ensure safe transportation, slurry pumps and components are packaged using export-grade methods such as reinforced wooden cases, pallets, moisture protection, and secure fastening. Heavy wet-end parts, bearing assemblies, and motors are typically packed separately to avoid impact damage during long-distance shipping. These packaging standards help protect equipment integrity during sea, air, or land transport.

International Shipping and Customs Support

Many slurry pump suppliers in China work closely with freight forwarders to provide efficient international logistics solutions. This includes arranging sea freight, air freight, or multimodal transport based on customer needs. Manufacturers often assist with export documents such as packing lists, invoices, certificates of origin, and customs declarations. For certain regions, additional compliance documents or inspection reports can be supplied to facilitate smooth customs clearance and on-time delivery.

Frequently Asked Questions About Chinese Slurry Pumps

1. What are slurry pumps used for?

Slurry pumps are designed to transport abrasive mixtures containing solids and liquids. They are widely used in mining, mineral processing, sand washing, dredging, power plant FGD systems, metallurgy, chemical processing, and tunnel construction. Chinese manufacturers supply models suitable for heavy-duty, medium-duty, and corrosive slurry environments.

2. Are slurry pumps made in China reliable?

Yes, Chinese slurry pumps have become increasingly reliable due to advancements in hydraulic design, casting processes, and material quality. Many factories produce pumps using high-chrome alloys, rubber linings, and precise machining. Reputable manufacturers follow strict quality control procedures and provide performance testing before shipment.

3. Can Chinese slurry pumps replace brands like Warman or Metso?

Many Chinese manufacturers offer pumps and parts compatible with popular global brands such as Warman, Metso, and GIW. Compatibility depends on the specific model, but in most cases, Chinese replacements can be installed without modifying the existing pipeline or foundation. This provides a cost-effective solution for maintenance and spare parts stocking.

4. How long is the delivery time?

Typical delivery time ranges from two to six weeks, depending on the pump model, size, and whether customization is required. Common pumps and spare parts are often kept in inventory, allowing faster shipping for urgent needs.

5. What materials are available for slurry pumps?

Chinese manufacturers offer a range of wear-resistant materials, including A05 and A49 high-chrome alloys, natural rubber, synthetic rubber, stainless steel, and custom metal formulations. Material selection depends on slurry abrasiveness, particle size, corrosiveness, and operating conditions.

6. Do you offer OEM or customization services?

Yes, many slurry pump suppliers in China provide OEM and ODM services. Customizations may include hydraulic design adjustments, material upgrades, pump base modifications, motor selection, and tailored configurations to match specific industrial requirements.

7. Is technical support available?

Manufacturers typically provide engineering consultation, pump selection guidance, installation instructions, operation manuals, and maintenance support. Some also offer remote troubleshooting and customized project recommendations.

8. How are slurry pumps packaged for export?

Slurry pumps are packaged in strong wooden cases or pallets with moisture protection and secure fastening. Heavy components such as impellers, casings, and bearing assemblies are often packed separately to ensure safe international transportation.

9. What information is needed to select the right pump?

To recommend an appropriate slurry pump, manufacturers typically need details such as required flow rate, head, slurry density, particle size, temperature, pH value, and application environment. This information ensures accurate model selection and stable long-term operation.