SiC Products

About SiC Degassing Rotor / Ceramic Degassing Rotor / Silicon Carbide Degassing Rotor

We specialize in supplying high-performance SiC degassing rotors for aluminum and aluminum alloy melt treatment. Designed for online degassing and refining systems, our rotors are produced from high-purity silicon carbide and sintered into nitride-bonded SiC (NSiC) to ensure long service life and stable performance in molten metal environments.

As a reliable source of ceramic degassing rotors in China, we offer rotor solutions that improve hydrogen removal efficiency, reduce non-metallic inclusions and enhance melt cleanliness. Compared with traditional graphite rotors, silicon carbide degassing rotors provide stronger corrosion resistance, wear resistance and oxidation stability, helping end-users extend operation cycles, minimize replacement frequency and achieve more consistent degassing results.

The dense SiC structure delivers low erosion, low gas absorption and zero contamination to the melt. Our SiC rotors maintain dimensional accuracy under continuous high-temperature operation and resist chemical attack from refining agents, making them ideal for online degassing units, holding furnaces and casting lines requiring reliable melt quality control.

Application

Aluminum and aluminum alloy online degassing systems

-

Refining and purification of molten metal before casting

-

Foundries, die casting and continuous casting lines

-

Degassing units for ADC, alloy wheel, aerospace and high-purity casting grades

Features of SiC Ceramic Filter

1. Strong Wear & Corrosion Resistance – long-lasting in molten aluminum and flux environments

2. Excellent Oxidation Resistance – stable performance with low surface degradation

3. High Thermal Shock Stability – resists cracking during rapid heating and cooling

4. Low Erosion & No Contamination – maintains melt purity and hydrogen removal efficiency

5. Longer Service Life – reduced downtime and replacement costs vs. graphite rotors

Comparison of Degassing Rotor Materials

High-Purity Self-Produced SiC Raw Material

Using high-grade petroleum coke, Hongyuan smelts SiC crystal independently and processes it into SiC grains as base material for our ceramic products.

We own a complete SiC product supply chain:

SiC Crystal Smelting → SiC Grains → SiC Ceramic Products, ensuring stable quality from raw material to finished products.

We adopt high-purity SiC raw material and a controlled NSiC bonding process to ensure strong structural integrity, high density and reliable long-term performance. Every SiC rotor is quality-tested for strength, dimensional stability and corrosion resistance before shipment.

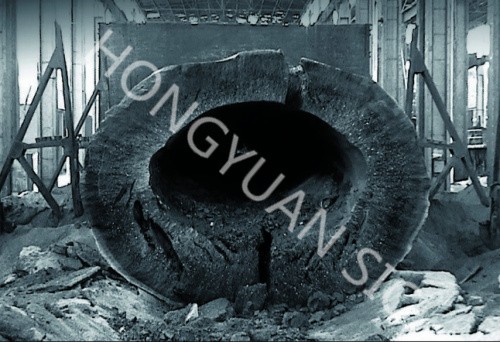

Advanced Equipments for Firing

Our automatic micro-computer controlled large-volume nitriding furnace—winner of the First Prize of China Machinery Industry Science & Technology Award for its residual-heat utilization system and patented utility design—ensures stable product quality and sintering performance.

As an original manufacturer of SiC ceramic products, Hongyuan offers direct-from-factory supply with stable quality and competitive prices.

Contac us

Hanjiang Hongyuan Xiangyang Silicon Carbide Special Ceramics Co.,Ltd.

Middle of Zhonghang Road, Aerospace Industrial Park, Xiangyang City, Hubei, China

Tel:+86-710-3155070

Mobile:+86-15072239775

Email: sales@hysic.com

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear