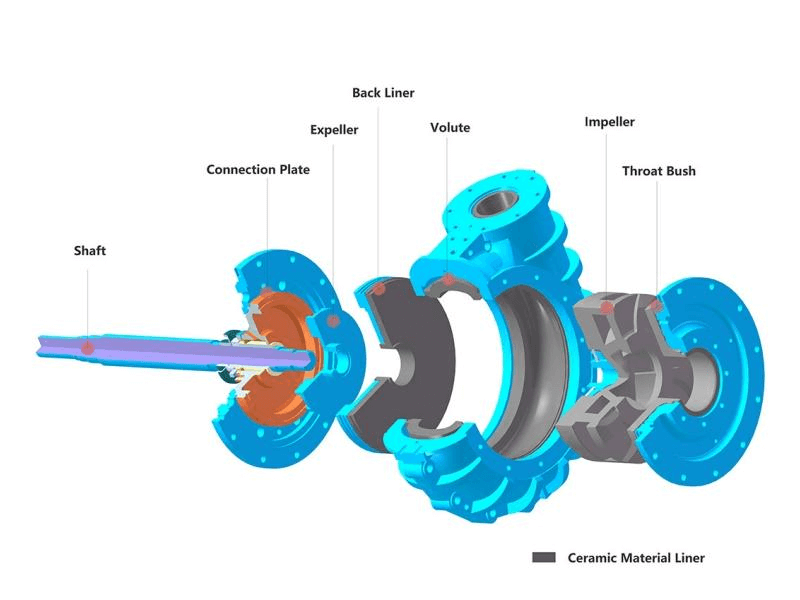

SiC Ceramic Horizontal Slurry Pump

• Significantly longer service life compared with metal pumps

• Excellent resistance to abrasion, corrosion, and impact

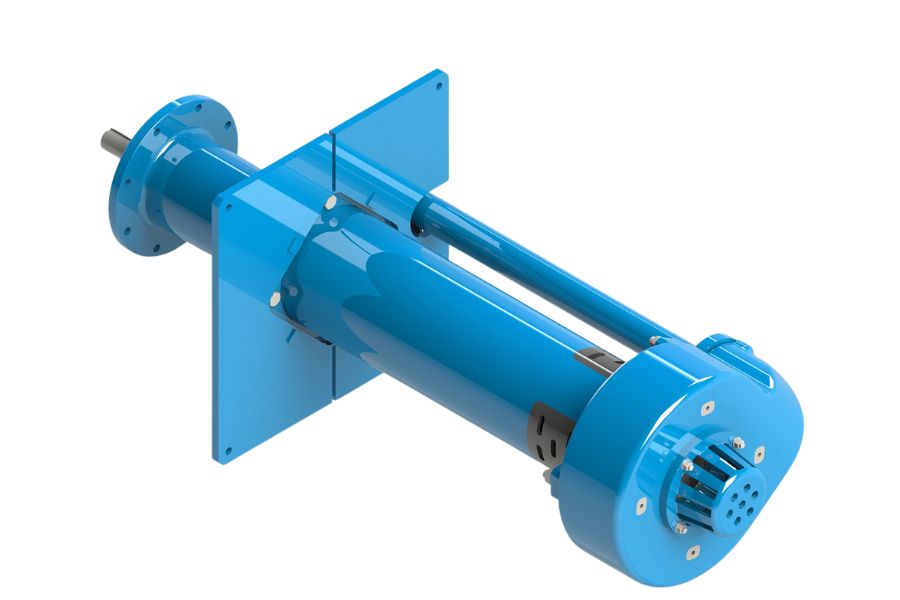

SiC Ceramic Vertical Slurry Pump

• Space-saving design for narrow pits or limited floor area

• Works efficiently while submerged in corrosive and abrasive slurries

☑ Exceptional Wear Resistance

Using advanced silicon carbide ceramic material, the pump can easily handle slurries with high solid content. The SiC surface resists cutting, scratching, and erosion caused by hard particles such as ore, sand, and gravel, resulting in significantly improved wear life compared with metal pumps.

☑ Outstanding Corrosion Resistance

SiC ceramics are chemically inert and maintain stable performance in strong acid and alkali environments (pH 0–12). Even under long-term exposure to corrosive media—such as seawater, sulfuric acid, chemical slurries, or desulfurization solutions—the material will not decompose, oxidize, or suffer large-scale corrosion.

☑ Long Service Life

With the advantages of silicon carbide and Hongyuan’s complete production chain—from SiC smelting and grit to ceramic pump components—the pumps deliver excellent durability and reliability. They can operate continuously with minimal wear and low maintenance requirements, achieving 4–6 times the service life of traditional metal slurry pumps.

☑ High Temperature & Thermal Shock Resistance

SiC ceramics maintain high mechanical strength and structural stability at elevated temperatures. The material resists thermal shock, making the pump suitable for high-temperature slurries and harsh thermal conditions without cracking or deformation.